NOV MONO INTRODUCES NEW API-COMPLIANT PROGRESSING CAVITY PUMPS FOR OIL AND GAS APPLICATIONS

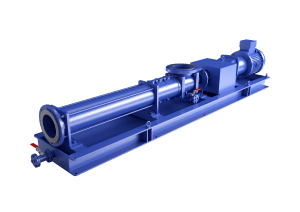

The launch of a new range of API 676-compliant progressing cavity (PC) pumps has focused attention on the ability of NOV Mono to supply pumping solutions designed specifically for oil and gas applications.

Mono’s PC technology is ideally suited to the typically arduous applications found in this sector, where solids-entrained multiphase fluids such as drilling muds, drill cuttings and produced waters need to be transferred with a steady flow and low shear. The new API 676 EZstripTM pumps provide a practical, reliable and proven solution which helps prevent emulsification, while also resisting the effects of abrasion without gas locking. This makes them ideal for many types of oil, gas and mud handling duties in drilling, exploration, production, processing and separation operations.

The new pumps feature a long-coupled, full-size base frame design that incorporates a drip tray in accordance with the API 676 Third edition. Supplied complete with a mechanical seal to API 682 Category 1, the pumps also incorporate Mono’s revolutionary EZstripTM technology which provides a quick and easy way to disassemble and fully maintain them in-situ. This can

dramatically reduce the time needed to replace a rotor, stator, coupling rod and drive train by up to 95%.

The self-priming pumps can be manufactured from different materials to suit different applications, ranging from mild and stainless steel through to traceable and NACE-certified duplex steels. They are bi-directional, which allows them to be mounted horizontally or vertically, and the positive seal formed by the interference fit between rotor and stator makes them ideal for low net positive suction head applications.

The gentle action of the new pumps prevents the emulsification of oil and water mixtures such as reject oil or separator feeds. The low velocity of the fluid through the pump, and the low rubbing velocity of the metal rotor against the stator, ensures low rates of abrasion and wear, while rotors with specialist coatings can also be supplied to provide additional wear and corrosion resistance.

In addition to the many standard features which are offered by API 676 EZstrip pumps, are options such as dry run protection, ATEX and API 682 seal systems.

Mono can also offer a range of artificial lift technologies, including electric well head drives, plunger lift and API-certified sucker rod pumps. These are designed for use in enhanced oil recovery and de-liquification operations, on both conventional and unconventional gas wells.

Mono’s track record as a supplier of PC pumps to the oil and gas industry is reinforced by the creation of a new Oil and Gas office in the U.K. to provide dedicated industry expertise and support for customers, as well as its associations with parent company, National Oilwell Varco (NOV), which has been a world-leader in providing advanced technology solutions to this sector since 1841.

The launch of new API 676 compliant progressing cavity (PC) pumps has focused attention on the ability of NOV Monoto supply pumping solutions designed for a wide range of applications in the oil and gas industry.

For more details visit www.mono-pumps.com or call +44 (0)23 8076 0000.