The benefits of in-line rheology measurement for manufacturing processes

The rheology of a fluid system governs both in-process efficiency and final product quality and is critical to the manufacturing of many products, including food such as sauces, liquid personal care such as shampoo and household cleaning products such as washing up liquid.

Traditional rheometry testing methods typically take place off-line with sampling required from the process stream. This takes time once you include obtaining the sample, sending to the quality control (QC) laboratory, and conducting internal checks. Then, once analysed, if the product does not meet specifications, it often must be scrapped or re-worked, resulting in large volumes of waste. As an example, it has been estimated that the annual product loss in liquid personal care products globally is the equivalent to 2,000,000 bathtubs. A large proportion of this waste could be reduced by the use of in-line rheology measurement.

Off-line measurements are also considered, with assumptions, as directly applicable to real process flows. This approach only provides a retrospective characterisation of a fluid sample, and the measurement does not account for any changes to the sample when extracted from process (e.g., cooling down, gelling / settling). It is often considered unsatisfactory when off-line rheological measurements are directly applied to process design and optimisation. For these reasons, conventional rheology methods can be enhanced to suit the needs of manufacturers’ processes, which are increasingly required to be more time efficient to meet growing demand.

A new era of rheology measurement

The Stream Sensing Rheometer, developed through electrical resistance rheometry (ERR), enables the characterisation of a fluid’s rheological properties within a pipe under steady conditions. ERR uses a novel arrangement of microelectrical tomography sensors which ensures that a complete velocity profile is attained with high sensitivity near to the pipe-wall

boundary. Due to their fundamental links, rheological properties are obtained through the direct measurement of the radial velocity profile within a pipe, as seen here.

The new technology allows rheology measurements to be conducted in-line, decreasing the overall production time, while ensuring higher quality control through real-time measurement and feedback, detecting problems quicker, therefore reducing waste and product loss. The range of benefits for the manufacturing process are vast and include:

- Providing a basis for real time product release to unlock process capacity

- Reducing waste through in-line process measurement

- Improving quality control responsiveness, process optimisation and improved formulation control

- Providing information to enhance process design

- Analysis of the velocity profile can provide additional data, such as if pipeline blockage has occurred

- The system can output further process status information, including mixedness

Modes of Operation

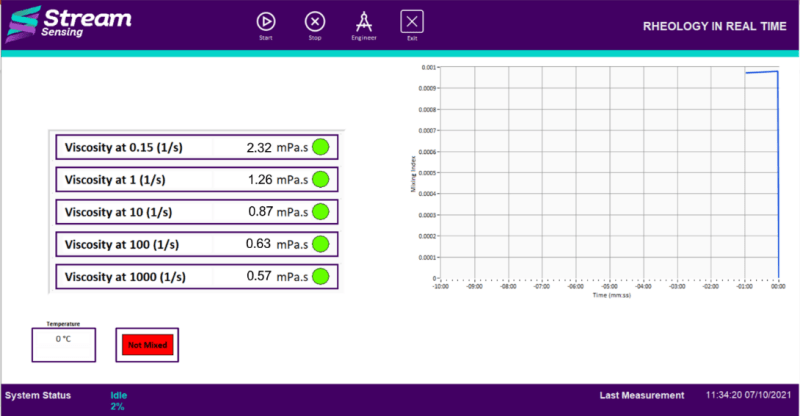

The Stream Sensing rheology instrument has different modes of operation. It can be used to provide real-time data to the plant’s control system for control and optimisation through digital communication protocols, such as Ethernet-IP. The system is also provided with a user interface, seen below, that allows users to measure rheology at the press of a button. This is a simple way of improving the efficiency of quality control processes in the laboratory through on-screen reporting, removing sampling and the potential for user error.

The digital manufacturing revolution

Ensuring the rheology is correct in liquid products is key to product quality and effectiveness and adoption of in-line technology could overcome some of the key constraints of traditional offline methods that we have seen in the industry to date.

Digital manufacturing presents an opportunity for greater sustainability and reduced operational and maintenance costs through process optimisation. As part of this manufacturing revolution, in-situ rheology measurements are highly desirable, since they deliver direct, real-time data. This provides essential, accurate information to control systems for plant managers and QC professionals about the product as it is being processed.

With the critical nature of rheology in processing, the ability to monitor rheology in-line, in real time could catapult rheometry from a quality control measurement tool, to one which is able to control and optimise processes and material structures.

For more information about real time rheology instruments, contact Stream Sensing https://www.streamsensing.com/#/.

Contact details

Stream Sensing Ltd.

Sunlight House

Quay Street

MANCHESTER

M3 3JZ

Ken Primrose – CEO